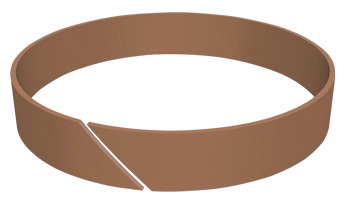

Ptfe Piston Rings

Guiding tapes 171 8.

Ptfe piston rings. A wide variety of teflon piston rings options are available to you such as standard or nonstandard. They significantly reduce a machines operating costs and in todays increasingly environmentally aware society make it easier for operators to fulfill stricter environmental legislation. The load on such a ring is much less than on the sealing piston ring. Ptfe ptfe polytetrafluoroethylene for a longer operating life.

They frequently have the same composition as the sealing rings but are made wider to increase the bearing area. Ptfe piston rings and guide rings rider rings for dry running applications are currently a focal point of technical development. They prevent metal to metal contact between the cylinder and the piston and enable the sealing rings to function properly. Application data sheet 184 9.

About 0 of these are seals 0 are caulking gun. When to use ptfe seals 7 3. Packing division europe warning user. 4 ptfe seal design guide parker hannifin corp.

Ptfe seal design guide parker hannifin corp. Ptfe piston rings have started to replace their carbon counterpart as ptfe rings offer greater durability a longer operating life and can be operated at various pressures velocities and temperatures. Virgin ptfe is too soft and has a very high coefficient of thermal expansion. Ptfe product lines 11 4.

The material i use was recommended to me by a supplier who i was in contact with when trying to obtain a material called flouroscint which is a mica loaded form of ptfe and has been used by a number of model engineers for piston rings. Continu ous in house research and development in the field of ultra high strength thermoplastic composite materials results in solutions for even the most demanding. Hence a material with a higher wear rate but lower abrasion may be used. Polytetrafluoroethylene ptfe seals and piston rings have started to replace their carbon counterpart as ptfe seals and rings offer greater durability have a longer operating life and can be operated at various pressures velocities and temperatures.

Anti extrusion rings 163 7. Slipper seals 109 6.